THG Crate Manager is an effective logistics management platform developed to improve the management and deployment of shipping crates.

Project Overview

THG Crate Manager enhances crate transportation performance by providing crate status tracking and automating processes, leading to increased time efficiency and cost reduction.

The THG Crate Manager is a specialized platform for logistics management, created to tackle the complex challenges involved in managing shipment of crates. This solution provides a complete ecosystem for managing logistics assets, prioritizing crate shipment and operational efficiency.

Industry

Country

USA

Platform

Mobile and Web App

Use Case

B2B

3.8s

Avg. Page Load Time

85%

Improved Performance

Business Challenges

The management of logistics can encounter various operational difficulties, particularly in the shipping crates and inventory tracking sectors. The THG Crate Manager encountered various problems prior to discovering the optimal solution.

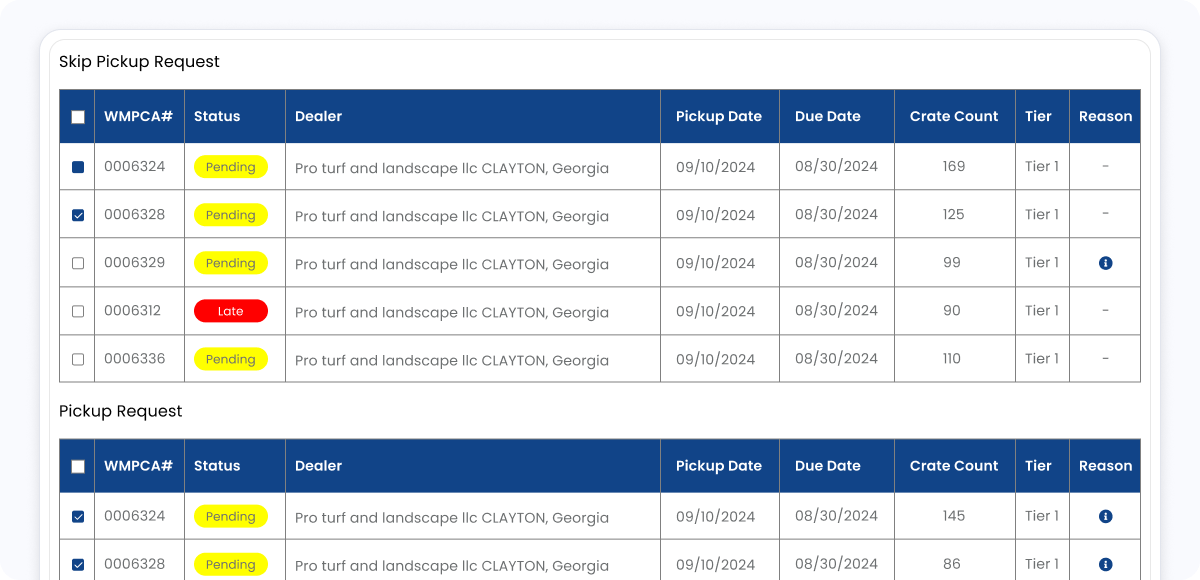

Manual Operations and Lack of Efficiency

The management of crate tracking and logistics relied on manual processes using files and spreadsheets, resulting in a slow and error-prone system that lacked real-time visibility.

Limited Data Insights

The lack of unified, real-time insights made it challenging for stakeholders to monitor crate usage and make informed decisions for logistical improvements.

Routing Complexity

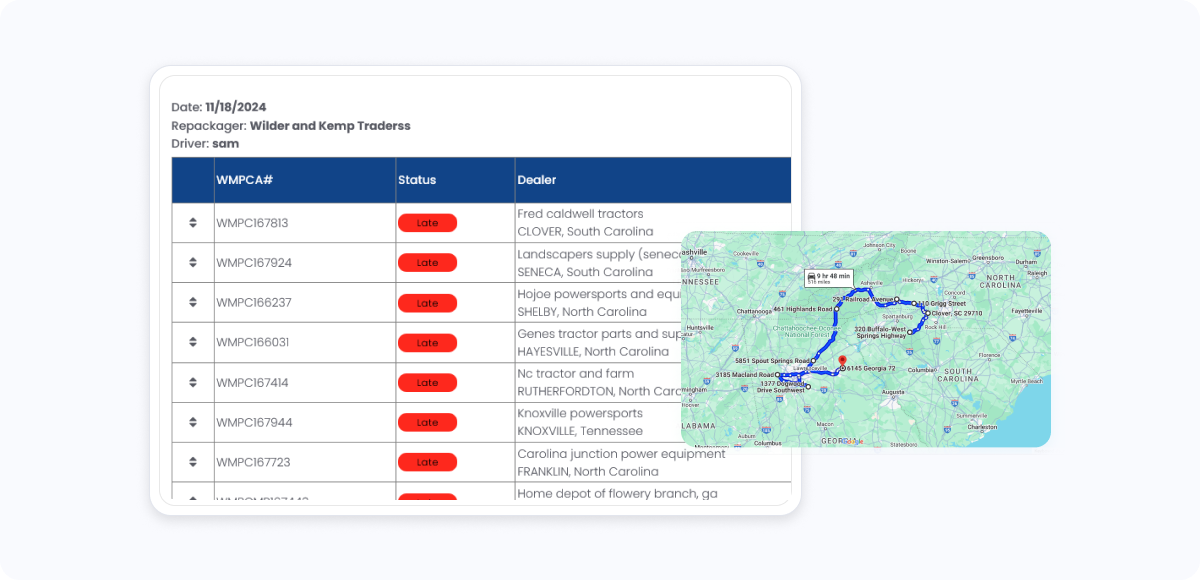

The owner personally planned routes and drop-off points without automation, a process that was both time-consuming and labor-intensive. This approach often led to delays, inefficient routes, and higher fuel costs due to the lack of optimization tools and real-time data.

The Solution

To address the operational inefficiencies and streamline the logistics process, Aipxperts developed a State-of-the-Art technology, THG Crate Manager. This platform is designed to modernize the management of crate shipments, automate delivery routing, and significantly enhance logistics efficiency.

The launch of the web and mobile application marked a significant transformation in the client’s operational processes. Manual tasks that contributed to delays and inefficiencies were replaced with streamlined, automated systems, greatly enhancing both speed and accuracy. A key advancement was the introduction of AI-powered routing, which drastically reduced the time required to generate crate shipping routes, accelerating the overall route planning process. Through digital transformation, the client achieved greater efficiency, reduced operational expenses, and improved delivery timelines, creating a solid foundation for future expansion.

Features implemented

Increased Operational Efficiency

Customized reports and analytics provided the client with the tools to make data-driven decisions, track key performance metrics, and identify opportunities for ongoing development.

Enhanced Resource Allocation

By prioritizing older pending crates first, AI routing ensures that resources are allocated based on urgency and delivery age. This enables smarter crate shipments, helping logistics teams maximize efficiency while reducing delivery delays and backlog.

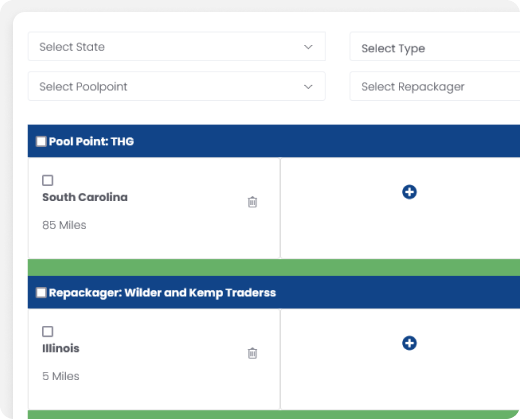

Optimized Inbound Logistics

The system improved the coordination and tracking of incoming crate shipments, enabling better planning and inventory management.

Mobility and Flexibility

The ability to access mobile technology allowed teams to maintain connectivity and stay informed from any place, enhancing field operations and quicker response times.

Tools & Technologies

The combination of strategically selected tools and technologies ensured the delivery of a flexible, high-performance platform capable of handling complex logistics operations, real-time tracking, and seamless user interactions across devices.

State-of-the-Art Technology driving THG Crate Manager

Ready to redefine digital experience?

Be it the Americas, EMEA, or APAC - our regional experts are available to offer solutions tailored to your needs.